As food distributors are looking to reduce waste and increase throughput to meet ever-growing consumer demands, having the right lift trucks and innovative solutions in place can make all the difference.

Whether you’re trying to reduce product touches, boost operator and pedestrian awareness or cut costs, Yale has what it takes to take your operations to the next level.

Need help finding the right solution? Connect with our food experts or see our lift trucks in action.

Challenges & Solutions

In an ever-changing competitive market, the food supply chain must utilize forklifts that streamline serviceability to reduce downtime, enhance operator confidence, eliminate battery maintenance and lower total cost of ownership.

Cut costs & increase uptime in refrigerated & cold storage warehouses

Increase capacity and streamline maintenance with the Yale® pantograph reach truck.

- Use up to 20% less energy for greater battery uptime

- Simplified serviceability helps reduce the amount of maintenance needed, saving you up to $2500 per truck/per year

- Can be disassembled to service or replace parts without taking off the carriage; saving up to 45 min per truck

Boost efficiency and improve order accuracy with the Yale® end rider pallet truck.

- Service faster and as much as 50% less often, reducing downtime

- Smart features to help shave seconds off tasks for greater throughput, 1-4 seconds per movement

- Precision pick allows control of speed and coast functions in both directions

Get advanced ergonomics and unmatched performance with the Yale® enclosed end rider pallet truck.

- Includes contoured, fully padded interior curbs back, hip, elbow and knee fatigue; cushioned floor mat reduces shock transfer

- Adjustable performance settings, the 192” forks accommodate up to 10 pallets per cycle, and industry-exclusive features capable of moving up to 25% more product

Strategize lift truck power options

Make the most out of scarce resources with simplified forklift battery maintenance, charging and replacement processes to help increase uptime and productivity.

- Choose from the industry’s widest range of power sources from a variety of brands to get the best return on investment

- Eliminate battery maintenance downtime

- Improve operator ergonomic seat position and comfort with increased head and leg room

- Conquer sustainability goals

Turnover and labor shortages continue to strain food distribution and cold storage operations. Equip your operators with innovative lift trucks and solutions engineered to enhance awareness and streamline workflows.

Food distribution & cold storage facilities require special engineered lift products & solutions

Your operations are unique, requiring tailor-made lift truck designs. Our large specialist engineering team is dedicated to customizing solutions to meet your specifications.

- Special equipment options utilizing sensing/proximity features to decelerate and reverse direction of travel when activated

- Pedestrian and operator awareness lights and alarms

- Operator convenience features designed to help increase motivation and productivity

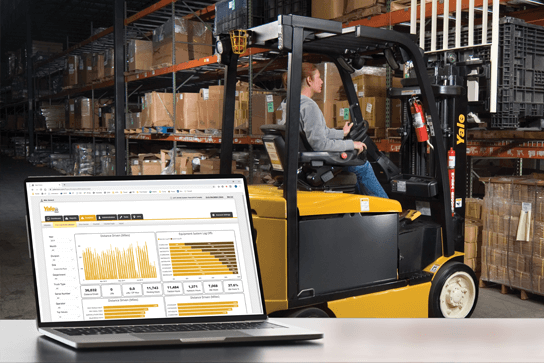

Forklift monitoring & tracking

Experience real-time lift truck and operator utilization, and how they are performing with Yale Vision telematics.

- Restrict truck access to approved operators only

- Receive usage metrics, impact detection and alerts

- Impact camera option increases operator accountability

- Digitize and enforce OSHA pre-shift checklist completion

Encourage forklift driver awareness & stability

Help reduce incidents with Yale® Reliant, a robust technology suite designed to reinforce lift truck operating best practices and support operator situational awareness, tailored to the unique challenges of warehouse operations..

- Monitor and detect objects in the path of travel and identify trucks/pedestrians out of line of sight

- Detect tagged trucks and pedestrians in proximity (360˚)

- Adjust travel speeds and hydraulic functions while maintaining truck stability

- Monitor forklift location, exclusion zones, lift height restrictions and more

New product introductions have expanded not only the variety of products, but the size and mix as well. Single SKU pallets no longer dominate the food chain, mixed/loose pallets now represent roughly 40% of the loads moved.

Maximize warehouse space & increase throughput

Maneuver confidently in tight spaces with the Yale® three-wheel stand-up electric counterbalance forklift.

- Take products in and out of tight spaces with a turning radius that means business, taking maneuverability to the next level

- Keep operators working confidently with the Hi-Vis™ mast, giving them both visibility and rigidity

- Eliminate up to 65% of shock and vibration transmitted to the operator, an advantage of 17% more isolation over leading competitors with the Yale® Smart Ride Floor System

Achieve greater slotting capacity with the Yale® low-level order picker.

- Use variable height picking processes to help increase SKU capacity and pick positions up to 400%, and slot capacity 140% within same footprint

- Place slower-moving SKUs above faster-moving ones for efficient access to frequently picked items

- Add case flow lanes to pick lines to accommodate more SKUs

Lift and move more with integrated, factory installed power options and attachments.

- Reclaim space by reducing to a ratio of one power source per lift truck going from lead-acid to lithium-ion batteries

- Increase productivity with attachments like the single double multi pallet handler built to carry multiple pallets at a time

- Forklifts and selected attachments are shipped turnkey and ready for delivery

Same-day delivery is becoming an expectation. To beat the competition and keep costs down, speed and agility are imperative.

Freezer & food storage forklift options

Equip operators with lift trucks engineered to withstand the toughest cooler/freezer environments, while promoting operator warmth and comfort.

- Help protect the truck from corrosion with sealed electronic components, closed cell rubber platform cushions and built-in drain holes to channel away moisture

- Siped, rubber drive tires are also available to increase traction control where damp floor conditions are present

- Offer reprieve from cold conditions with operator comfort packages, like optional fully insulated cold storage cabins with heated windows and doors

Direct store delivery (DSD) forklift options

Give your drivers the confidence to move more cases easier, and in less time from trailer lift gates, across unforgiving terrain and through narrow convenience store aisles.

- Empower your operators with features that increase maneuverability in tight spaces and on the lift gate

- Defy charging limitations with opportunity charging to help drivers achieve up to 11% greater productivity

- Keep loads stable and secure with auxiliary traction and moveable load backrest

- Make every delivery with charging capabilities up to 2x faster and last longer with lithium-ion batteries

Resources & Support

Find the right truck for your application while discovering proven solutions and strategies food distribution and cold storage operations can apply today.