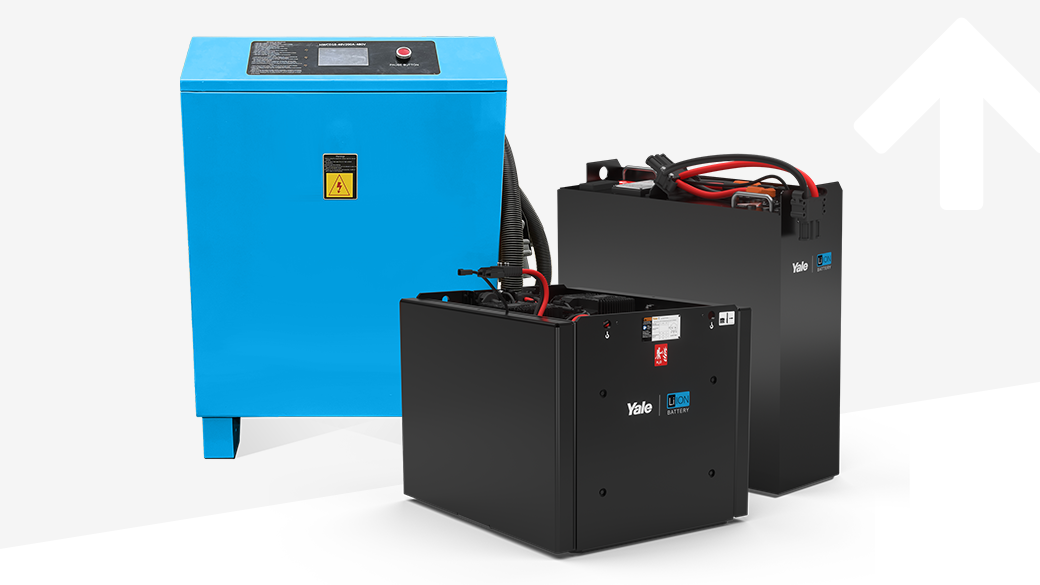

The high energy density of Yale lithium-ion batteries supports long run times for fast-paced warehouses. The Lithium Iron Phosphate (LFP) chemistry at the core offers improved heat stability and tolerance, and longer life compared with other battery chemistries.