Safety

Automotive manufacturing reported injury and illness rates of more than double the national average of the private sector.

- Use telematics to track lift truck access and provide training updates

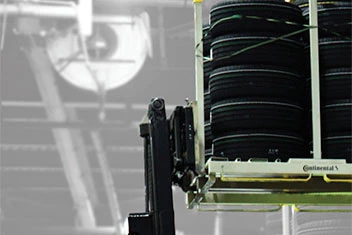

- Implement automated solutions and redirect workers to more value-added tasks

- Evaluate whether forklift awareness solutions will help increase awareness and minimize risk in your facility